Ultra-high temperature vertical graphitization furnace is commonly used in Ultra-High Temperature Furnace within 3000 ℃, used for a variety of high thermal conductivity graphite film (PI film), lithium battery anode materials, carbon materials, carbonisation and graphitization of carbon materials production of carbon materials carbonisation, graphitization; carbon fibre filament sizing graphitization and other materials can be sintered in the carbon environment.

Product Characteristics

- 3000 ℃, commonly used temperature 2900 ℃.

- the working atmosphere: vacuum replacement Ar2, N2 protection (micro-positive pressure)

- temperature measurement: far-infrared optical temperature measurement temperature measurement range 1000 ~ 3000 ℃ or 0 ~ 3000 ℃; temperature measurement accuracy: 0.2 ~ 0.75%.

- temperature control: programme control and manual control; temperature control accuracy: ± 1 ℃

- Equipment adopts medium frequency power induction heating, high efficiency: unique furnace chamber design, greatly improving the furnace temperature uniformity. Limit heating speed: 200 ℃ / min (empty furnace, depending on the volume of the high-temperature zone and the structure of the furnace chamber) furnace temperature uniformity ± 10 ℃, temperature control accuracy ± 1 ℃.

- low energy consumption: thickened alumina insulation material, heat insulation and refractory effect, heat loss is small, heating speed.

- Long service life of wearing parts: the bottom of crucible is padded with high-strength hard composite felt to ensure that the graphite crucible is flat and uniformly stressed at high temperature, which is 1.2 times of the service life of similar products.

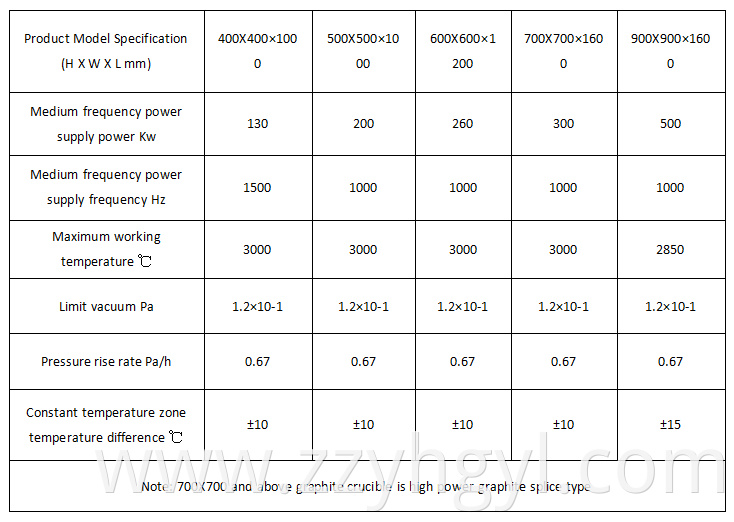

Product Parameter

Product Showcase