The medium frequency Tungsten Carbide Sintering Furnace is an Intermittent Induction Heating Furnace. It is mainly used in the cemented carbide and powder metallurgy industries to produce various particle sizes of tungsten carbide powder, titanium carbide powder, vanadium carbide powder and other metal powders and composite metal powders.

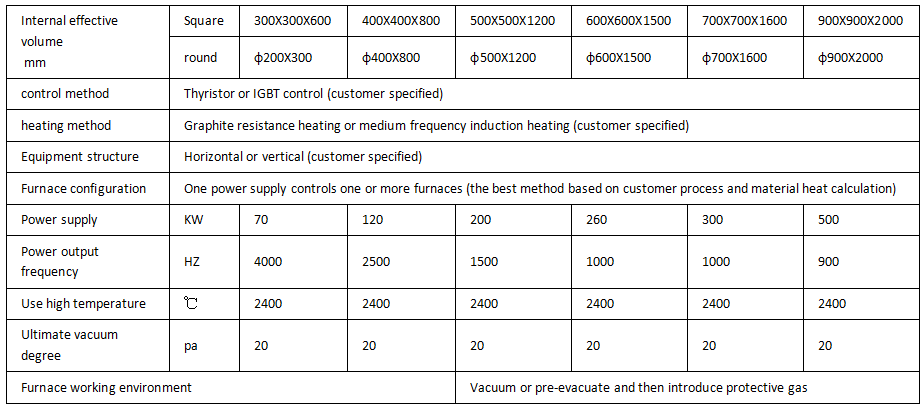

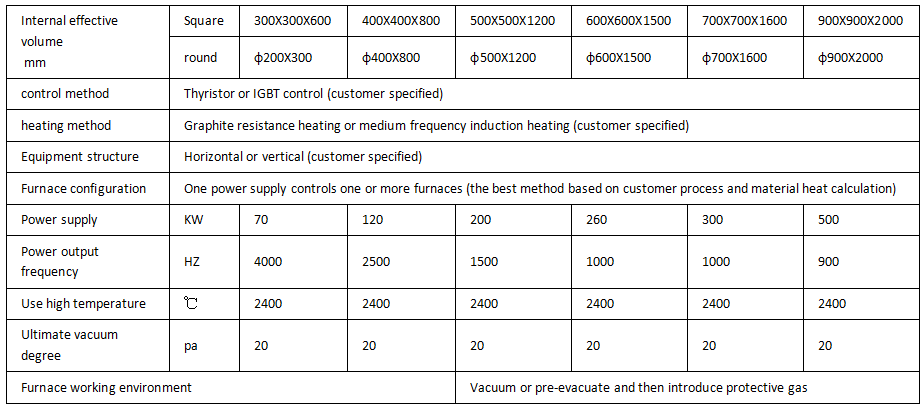

Product Parameter

Product Characteristics

1. 2400℃ Ultra-High Temperature Furnace body, compatible with fine, medium and coarse particle material WC powder and composite material carbonization heating process

2. Adopt a digital display programmable intelligent temperature control system to fully automatically complete the temperature measurement and temperature control process with high precision. The system can heat up according to a given heating curve, and can store twenty different process heating curves with a total of 400 segments.

3. Adopt pure water cooling system; digital flow monitoring system, use high-performance medium frequency contactor to automatically switch the furnace body; comprehensive PLC water, electricity, gas automatic control and protection system.

Product Showcase